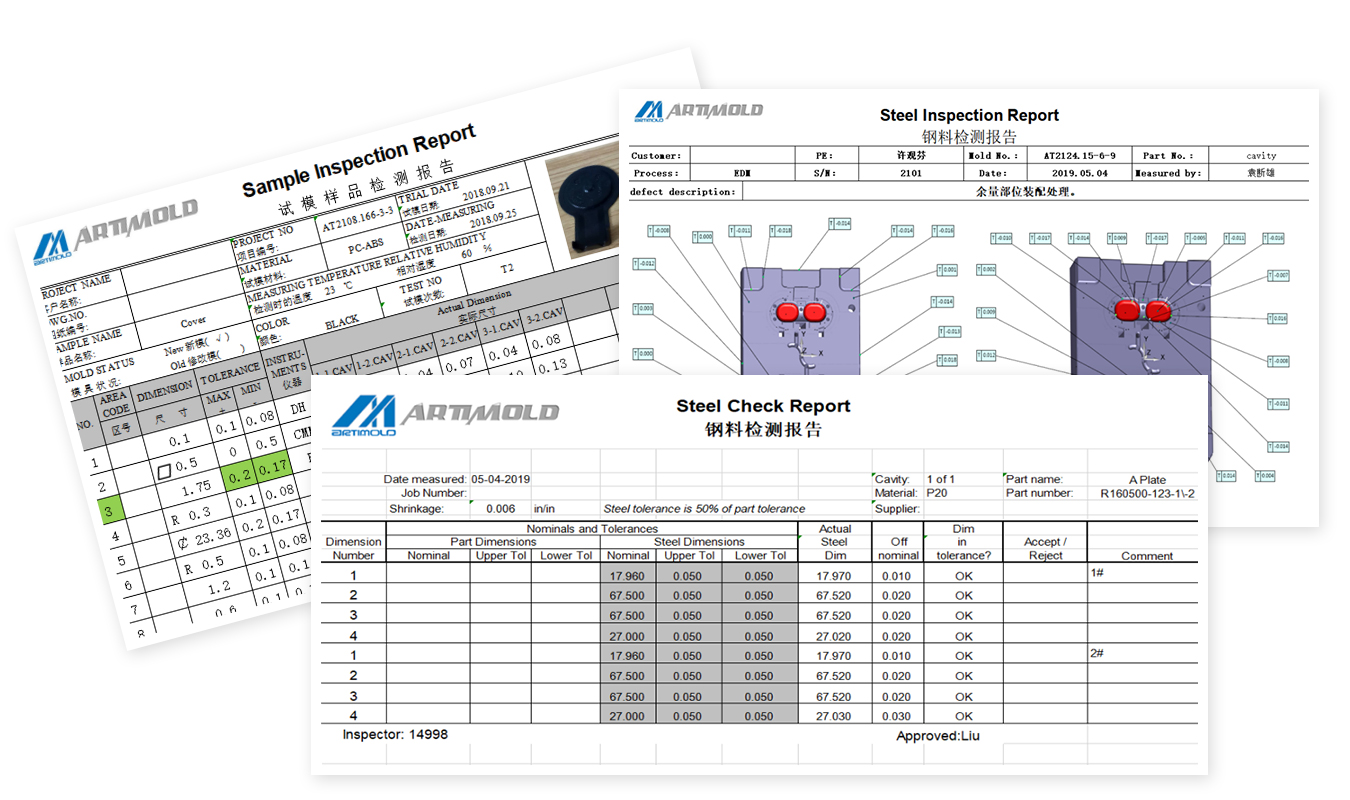

All operation are under ISO9001 procedure.

As a responsible company, we are guided by our basic principle of zero-defect. That is why we respect and value ambitious quality management as a work step that completes the entire process and guarantees the expected quality to the client. We use the principle of systematic monitoring of processes and start with quality analysis from the very begining the design processes. And our activities are checked regularly by certifications in accordance with ISO9001:2015 and through audits of our clients' processes and systems.

Mold Main QA Procedures:

■ Moldbase inspection

■ Insert inspection

■ Tool components inspection

■ Electrode inspection

■ Pre-assembly inspection

■ Samples inspection

■ Pre-delivery inspection

Plastic Injection Control Process:

■ First-article inspection on critical dimensions and comparison with approved sample.

■ A visual inspection performed by our trained line workers.

■ Parts are inspected one time for each 2 hours at station by IPQC

■ Finally, the acceptable parts are boxed, counted, and inspected again by our IPQC before they were moved to warehouse. And then, the pars are ready for shipments.

Shenzhen Artimold Industry Limited

Address: Building B27, Tantou Western Industrial Area, Songgang, Bao’an, Shenzhen, 518105, China

Website: www.artimold.com

E-mail : Tim.chen@artimold.com

Mobile Website